In the just-concluded “Far East Lecture- the Advanced Symposium on the Subject of Digital Transformation of Smart Manufacturing”, many experts and bench-marking enterprises in the manufacturing industry brought wonderful sharing one after another. As the last lecture, Far East also shared the achievements of digital transformation. Under the trend of intelligent manufacturing transformation and upgrading, Far East Holding Group has laid out digital transformation in advance, firmly seized the development opportunity and kept up with the pace of intelligent manufacturing era.

Digital strategy, leading the transformation and upgrading of intelligent manufacturing

The first is a change of mindset. The intelligent and digital transformation of enterprises cannot be completed overnight. It must be explored through a lot of time and practice. Considering the digital transformation from the perspective of business and production demands, a lot of energy, material resources, financial resource and human resources will be invested during this period, which may not have significant effects in the short term. This requires enterprises, from senior leaders to grass-roots staff, to fully understand the benefits brought by digital transformation and upgrading of enterprises, to fully establish a digital transformation culture, to firmly implement the digital transformation.

The second is to have a clear digital strategy. Digital strategy relies on enterprise strategy, starting from top-level planning, conducting digital business guided by business strategy and business demand. Meanwhile, list digital transformation as a key work, and make each subsidiary undertake the performance index.

On the road of digital transformation, Far East always adheres to comprehensive digitalization and intelligentization, and firmly promotes transformation and upgrading.

Digital transformation drives the construction of smart factories

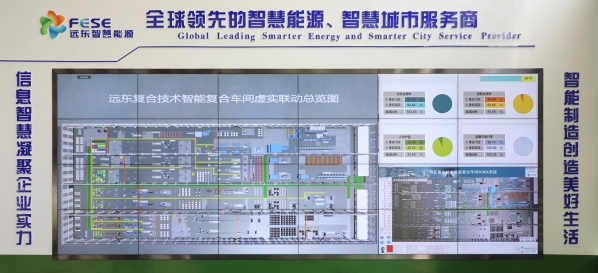

In the Far East Composite-Tech workshop, the industrial Internet system -- SCADA system was firstly built. It adopted information technology and control system such as field bus, Ethernet, Internet of Things and distributed control system, and carried out real-time monitoring through three-dimensional modelling of the factory and layout simulation between equipment and processes.

SCADA system can be used for testing and operation of single equipment operation status index, cargo location customization, pallet standardization and automatic distribution of production materials. AGV automatic unmanned vehicle can play a great role in material transportation. It not only has the advantages of fast speed, high accuracy, strong flexibility, safety and reliability but also can work continuously for 24 hours to improve production efficiency.

The real-time production situation of the workshop, the running status of the equipment on each production line, which equipment is abnormal, which production line is the most efficient, how much energy is consumed in production, and how good the product quality is all clear at a glance on the background screen.

At the same time, MES connects with SCADA for system data, and SCADA gets task list information, shift information and KPI value from MES. MES obtains equipment information such as equipment running time and energy consumption from SCADA. Abnormal data will be automatically pushed to the mobile phone for prompt feedback, rapid response and accurate decision.

By optimizing the production layout, introducing automatic and intelligent equipment and automatically controlling the production process, the qualified rate of products has been increased by nearly 3 percentage points, the labor cost has been reduced by 30%, the per-capita output value has been increased by 28%, the manufacturing cost has been reduced by 1.7%, and the inventory pressure has been reduced by 33%.

Freight Yard Cable, automatic positioning

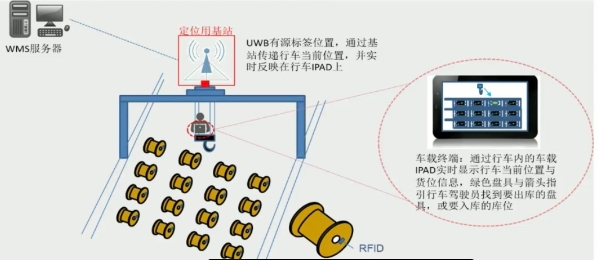

In the past, the inventory time of the cable freight yard was long, low accuracy and low efficiency. By assembling and locating base station equipment on freight yard, IPAD could dynamically display the position of cargo space in the freight yard and record the position in storage when driving, and record the position in the system when unloading

According to the automatic display of the existing goods in the system, the automatic reporting and checking instrument is used in the process of inventory counting. The efficiency of goods releasing and unloading is increased by more than two times, and the efficiency of inventory counting is increased by more than nine times.

Intelligent production lines will facilitate the R&D of new energy

Far East Battery Co., Ltd has always been committed to the development of the lithium battery products with high safety, long life and high specific energy, adhering to the all-round upgrade, and boasting domestic advanced digital equipment and production lines.

Through highly intelligent production equipment, the whole process of loading and unloading could achieve automatic logistic scheduling, accurately controlling the current, voltage and temperature. It can also realize charge and discharge engineering management and data management of the battery under the control of the scheduling system.

In order to ensure the traceability of key data, the battery was fully tested by high-precision instruments with efficient process and high-test accuracy. The roadway stacker automatically pick up and discharge the goods on shelf while completing the data uploading at the same time.

DTS temperature monitoring and smoke alarms cover all production areas, ensuring high stability, high accuracy and high safety while producing efficiently.

Cultivating Digital Talent, Building New Competitiveness

Digital talents are the key factor for enterprises to promote digital transformation. The workers in traditional manufacturing enterprises are generally of low technical level. In the process of intelligent manufacturing transformation, enterprises also cultivate excellent digital talents through constant practice.

From the most basic human processing to the transformation of technology management and process management, the upgrading of equipment system is also the upgrading of digital talent training.

At the critical moment of the digital transformation of the manufacturing industry, Far East firmly promotes the implementation of intelligent and digital transformation by laying out top-level design in advance, so as to forge far East intelligent manufacturing and make constant progress on the road of transformation and upgrading of Made in China.